The PCCL has access to well-equipped laboratories. They contain the infrastructure necessary for PCCL projects - from basic electronic equipment to a surface topography measuring system for the non-contact measurement of polymer surfaces. Outside organisations can take advantage of the PCCL equipment at market prices in sub-contracted research projects.

Enclosed you can find a list of all our equipment:

Main  Equipment

Equipment

|

Highspeed Camera Photron SA1 The Photron SA1 is a world leading highspeed camera system which provides a maximum framerate of 675.000fps. This system is mainly used for material characterization and deformation analysis of materials under impact loading. Since the system just consists of the camera unit and a notebook for the data recording, it is highly portable and flexible. With interchangeable lenses it is possible to record events from millimeter scale up to meter scale (e.g. automotive crash situation). |

Specifications:

|

|

Thermal conductivity mesurement system The HotDisk system is based on the Transient Plane Source method, which is a fast technique for simultaneously measuring the thermal conductivity, the thermal diffusivity and the specific heat. The thermal properties can be measured in the range of 0.01 W/(m K) to 400 W/(m K) at temperatures ranging from room temperature up to 1000 K. The system can measure the thermal properties of a variety of materials, including low conductivity plastics or ceramics and granular materials. |

|

Size exclusion chromatography (SEC) This method, also known as gel permeation chromatography, GPC, is used for analysis of oligomeric and polymeric molecules. In a chromatographic column the molecules are separated accoding to their molecular size and the fractions derived are detected as they leave the column. Main field of application is the determination of molar mass distributions and the determination of long chain branching of polymers soluble at room temperature. |

|

IR Spectrophotometer with integrating sphere The PerkinElmer Spectrum GX is a high performance IR spectrophotometer for the characterization and identification of materials and for the determination of optical properties of both solids and liquids in the wavelength range from 1,4 to 27 ?m. Next to the standard sample compartment for measuring specular transmittance spectra, the Spectrum GX is equipped with a 100 mm integrating sphere, which allows the measurement of total and diffuse transmittance and reflectance spectra. The characterization of the surface and near surface regions can be done with two different ATR devices. The Pike Miracle ATR device, equipped with a diamond crystal, is a universal ATR sampling accessory for analysis of solids, liquids, pastes and gels,whereas the Pike Veemax II, equipped with a ZnSE and Ge crystal, is a variable angle single reflection ATR for depth profile (from 0,5 to 10 ?m) studies. The IR spectrophotometer is used for: |

|

|

Modular compact rheometer, Paar Physica MCR501 The rotational rheometer MCR501 by Anton Paar GmbH is used for measurements of the flow characteristics of polymer melts in the low shear rate range. Additionally both elastic and viscous properties may be determined by means of discrete relaxation time spectra. The rheometer is capable to perform a wide range of steady state and dynamic tests in both stress-controlled (CSS) and rate-controlled (CSR) mode. Furthermore, different test types can be combined in order to help simulating various process and service conditions. Amongst others, it is possible to perform following measurements: |

The rheometer may be equipped with an electrically heated chamber (up to 400°C), a convection temperature device (up to 600°C) and an extensive range of accessories. The extensional rheology system SER, developed by Dr. Martin Sentmanat (Xpansion Instruments) can be used for extensional measurements on filled and unfilled polymeric solids or melts over a large temperature and deformation-rate range. Available software package also allows for the calculation of an average molecular weight and average molecular weight distribution from continuous relaxation time spectra and vice versa. |

|

LC-MS-System LC-MS/MS is a coupling of two different techniques, HPLC (high performance liquid chromatography) and mass spectroscopy (MS). HPLC separates molecules according to their different absorption behaviour and is combined with MS, an additional separation and analytical procedure. Main field of application is the identification of organic stabilizer systems in plastics. |

Characteristics of the LC-MS/MS system

MS part:

|

|

Bose ElectroForce 3200 ElectroForce 3200 test instruments from Bose provide exceptional fidelity, precision and versatility for a variety of test applications. Our newest ElectroForce 3200 test instrument features a dynamic axial force capability up to 500 N and at a maximal axial displacement of 6.25 mm. The torsion unit has the maximum torque capacity of 2.8 Nm and 10 full revolutions are possible. The test system can perform cyclic tests over a frequency range from 1 cycle per day to 100 Hz. Dynamic performance is dependent on test specimen characteristics, fixturing and test specimen configuration. Furthermore, the test system is equipped with temperature chamber and test can be performed from -60 °C to 300 °C. The test system is used for both conventional dynamic mechanical analyses (sine waveform in uniaxial loading) of thermoplastics and elastomers and for advanced (pulse waveform and multiaxial loading). Moreover, due to the high stroke flexibility, fatigue tests on various elastomer and small thermoplastic specimens are also conducted. |

|

Collin Laboratory Coextrusion Line The Collin laboratory-coextrusion line allows for the production of films of up to 5 layers with a maximum thickness of 1,3mm. Both individual layer thickness and film build up may be varied. The coextrusion line consists of a main extruder (D=30mm, L/D=30) and two subsidiary extruders (D=20mm, L/D=25). All extruders are equipped with a melt filtration unit and are connected to feed block and flat film die (W=250mm) by means of melt tubes. The possibility to use different screws or screw setups (e.g. by adding shear and mixing units) and a devolatilizing section broadens the applicability of the coextrusion line for a large number of material types and blends. The take-off unit consists of separately temperature controlled chill-rolls, an air knife, an edge trimming unit with edge-trim wind up and the possibility to wind up the film by either a center winder or peripheral winder. The entire extrusion unit is computer-controllable. Hence, it is possible to synchronize the unit and set required layer thicknesses and take-off speed directly via the computer software. |

|

Full-Field Strain Analysis Systems Two systems are available for full-field strain analysis: |

|

Preparative Fractionation of homo- and copolymers The "PREP-mc2 plus" system of PolymerChar allows an automated fractionation of polymers according to their molar mass and composition where a maximum of fifteen fractions of the polymer can be obtained in a semi-preparative scale. Fractionation can be carried out in one, or parallel, in two reactors. Fractionation according to molar mass (homopolymers and copolymers): The polymer is dissolved at a constant temperature in solvent/non-solvent-mixtures of various quality. Fractions of increasing molar mass are obtained and transfered into collecting bottles for further preparation. |

| Fractionation according to molar mass (homopolymers and copolymers): The polymer is dissolved at a constant temperature in solvent/non-solvent-mixtures of various quality. Fractions of increasing molar mass are obtained and transfered into collecting bottles for further preparation. |

|

| Fractionation according to composition (branched homopolymers and copolymers): At an elevated temperature the polymer is dissolved in an appropriate solvent and the solution obtained subsequently cooled down using a constant temperature gradient. Due to different precipitation or crystallization behaviour of the phases of the polymer, fractions of various degree of branching or composition are obtained. Subsequent heating using discrete temperature steps leads to a successive dissolution of the different phases which are transfered into collection bottles for further preparation. ...video |

|

UV/Vis/NIR spectrophotometer with integrating sphere The PerkinElmer Lambda 950 is a high performance UV/Vis/NIR spectrophotometer for the determination of optical properties of both solids and liquids in the wavelength range from 175 to 3300 nm. The Lambda 950 is equipped with a snip-in 150 mm integrating sphere, which allows for measurement of total and diffuse transmittance and reflectance. |

The UV/Vis/NIR spectrophotometer is used for the optical characterization of:

|

|

Optical 3D Digitizing System The optical 3D digitizing system ATOS II SO from GOM records the entire shape of components and tooling. The measuring system is non-contact and is used to measure small and medium-sized components. |

| The measurement method is based on the principle of triangulation. A projection unit projects different patterns of stripes onto the object to be measured. The patterns produced are evaluated by two cameras. Based on the image equations, highly precise 3D coordinates are calculated automatically for every pixel. | |

The main advantages of 3D digitizing are:

|

|

| For quality assurance purposes the digitized dimensions of the component can be superimposed on the original CAD model. This comparison of target and actual dimensions can be used, e.g. to check whether a part is within tolerance or which part of a component has warped. ...video |

|

Confocal Microscope (Topography surface measurement system) The FRT MicroProf is a 3D optical measuring system for computer-supported 3D contour and surface roughness measurements. The measuring system is a non-destructive, non-contact measurement system suitable for all surface types and is used to measure small and micro-components for research, development or failure analysis purposes. |

| The advantages of the MicroProf optical 3D measurement system are a high resolution and a high measurement speed. | |

| The measurement method is based on the principle of chromatic aberration. White light is focused on the component and the position of the object in the measuring field is found from the spectral distribution of the light deflected at the surface. | |

| The MicroProf is used to measure lateral and vertical distances and angles, to construct histograms and ultimate load curves and to measure the surface roughness and waviness according to DIN EN ISO standards. Surface and volume calculations can be carried out and a surface can be viewed three dimensionally from any angle. ...video |

|

TREF (Temperature Rising Elution Fractionation) The PolymerChar TREF 200 is used to calculate the distribution of side chains and the composition of polymers and copolymers (composition distribution). |

| It is based on the principal that different polymer fractions crystallise differently in solution. | |

| Fractioning occurs in a two-step process. | |

| In the crystallisation step, the different polymer fractions form onion-like layers around an inert TREF packing material during cooling. Due to the different crystallisation behaviour of the different fractions, the degree of short chain branching increases with the number of layers. | |

| In the second step the polymer fraction layers are solved at increasing temperature and eluted. The degree of short chain branching of the eluted fractions degreases with increasing temperature. Detection is by means of infra red radiation at constant wavelength. |

|

IR Thermography The thermography systems of the French manufacturer CEDIP Infrared Systems are the latest versions of Focal Plane Array (FPA) infra red detectors available internationally for high-end use. |

| By using highly sensitive quantum detectors a high thermal resolution together with a high image frequency is achievable. | |

IR thermography is used in the following areas:

...video |

|

Microtribology Test System The UMT-2 precision tribometer from CETR is used to investigate and simulate friction and wear processes in sliding solid bodies, boundary and mixed friction and elastohydro-dynamics. |

| Both models and components can be tested. | |

| The UMT is capable of circular, linear and rapidly changing movements in all directions with 0.001 to 5000 rev/min. | |

| All tribological properties such as frictional force, torque, normal load, temperature and wear depth can be measured and recorded during the test at a sampling rate of 20 kHz. ...video |

|

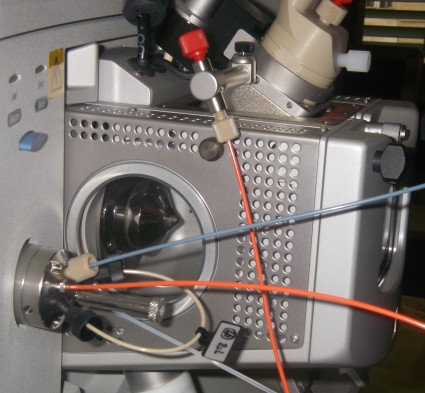

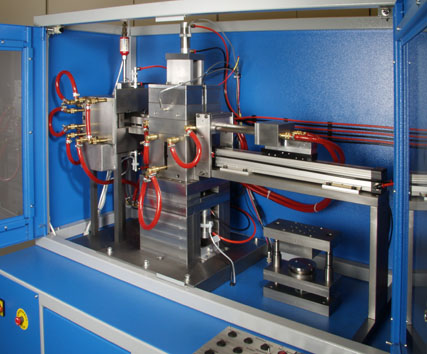

pvT System In contrast to typical pvT system on the market which use relatively slow cooling rates and are therefore do not reflect industrial practice, the pvT system developed by the PCCL can reach a significantly higher cooling rate by using a disk shaped specimen with a diameter of 60mm and variable thickness of between 1 and 10 mm. |

| In addition the faces can be cooled similar to in an injection moulding machine. | |

| The specimen is heated to testing temperature in the furnace chamber and transported into the measuring chamber via a pneumatic carriage. | |

| Here, pressure is applied to the sample by a hydraulic ram and the change in volume with temperature and pressure is measured using a high-precision position sensor allowing the shrinkage behaviour of plastics to be observed under realistic conditions. ...video |

|

Micro compounder twin screw mixer The MiniLab combines compounding and viscosity tests on small samples. The rig is based on the established conical twin screw technology with co- or counter rotating screws. |

| A pneumatic ram ensures easy sample feed. An integrated bypass valve allows the sample materials to be circulated in a backflow channel with slit capillaries or the extrusion of the material for further tests. | |

| The rapid cooling and a divided, hinged extruder tube allow the user to freeze the compound for further tests. | |

| The MiniLab functions as a stand-alone facility with a data export function or can be completely computer-controlled. ...video |

|

Server-hydraulic tester The MTS 858 system is used to document the mechanical properties of materials under different loading conditions (tension, pressure and bending; static, monotonic and cyclical loading). |

| The max. stroke is 100mm, the max. velocity is 0.5m/s and the max. test frequency is 100Hz. | |

| The system is equipped with a load cell capable of measuring up to 15 kN and is used primarily for fatigue tests on various polymers. ...video |

The various facilities of our scientific partners are also available to us for the characterisation of polymers.