“Detect and quantify the immeasurable”

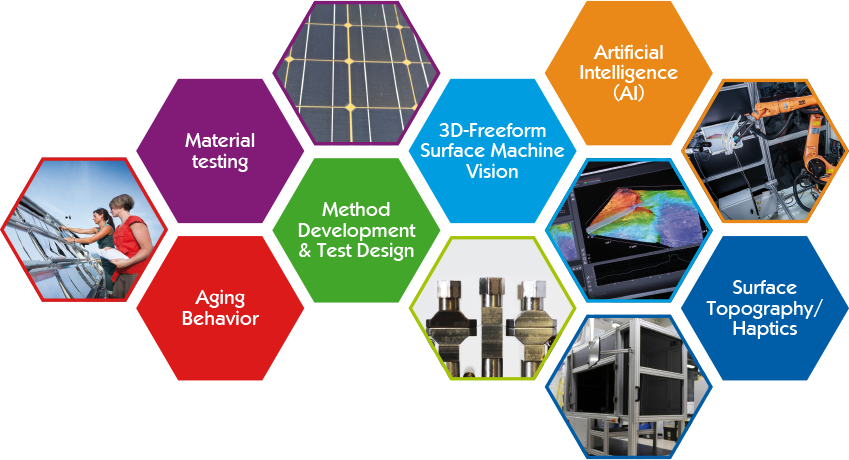

Competences and technical applications

Quality, reliability and lifetime of polymers and polymer products are key issues in many technical applications. Comprehensive knowledge of functional properties of polymers as well as changes in the properties during processing and product life time is essential with respect to material performance, quality assurance, product safety and warranty. The Smart Material and Surface Testing division comprises two distinct research groups.

The main focus of the multi-disciplinary research team of the Aging Behavior of Polymers group is the characterization and quantification of functional properties of polymeric materials that are crucial for performance in their respective fields of application. Based on material science principles, the factors responsible for the reliability of a polymeric component are quantified and measured. This includes chemical, optical, thermal, thermo-mechanical and acoustic properties of polymeric materials. Moreover, the description of chemical and physical aging processes and their impacts on the polymer property profile and overall performance is of interest. A special field of research is the degradation behavior of polymeric materials in photovoltaic modules, with a focus on interactions of polymers and inorganic materials such as metals.

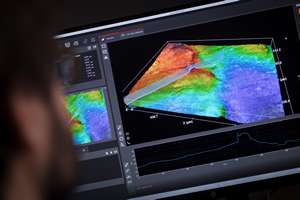

The Robot Vision and Artificial Intelligence research group focuses on the development of machine vision and machine learning solutions for quality inspection of all kinds of material surfaces and 3D-freeform components. New machine learning and deep learning methods allow for smart, automated detection and classification of patterns and anomalies in big data clouds. Artificial intelligence is applied both to surface defect detection and the control of production processes. Full inspection of 3D-freeform surfaces, high detection speed and results close to human perception are three major benefits of the PCCL inspection systems. The information on surface quality can be fed back into the production line, where self-intelligent routines control the quality and the efficiency of the production process. These activities are essential aspects for the smart production of polymer parts as is typical of the Industry 4.0 paradigm. Another field of research is the development of new approaches to the detection and characterization of touch-feel properties of material and product surfaces. The quantification of topographical, tribological, vibration and mechanical compliance of a surface leads to a comprehensive image of the tactile behavior of bulk material surfaces and coatings. Furthermore, new methodologies for the detection and analysis of micro- and nano-scaled materials and surface structures were added to the portfolio.

The Robot Vision and Artificial Intelligence research group focuses on the development of machine vision and machine learning solutions for quality inspection of all kinds of material surfaces and 3D-freeform components. New machine learning and deep learning methods allow for smart, automated detection and classification of patterns and anomalies in big data clouds. Artificial intelligence is applied both to surface defect detection and the control of production processes. Full inspection of 3D-freeform surfaces, high detection speed and results close to human perception are three major benefits of the PCCL inspection systems. The information on surface quality can be fed back into the production line, where self-intelligent routines control the quality and the efficiency of the production process. These activities are essential aspects for the smart production of polymer parts as is typical of the Industry 4.0 paradigm. Another field of research is the development of new approaches to the detection and characterization of touch-feel properties of material and product surfaces. The quantification of topographical, tribological, vibration and mechanical compliance of a surface leads to a comprehensive image of the tactile behavior of bulk material surfaces and coatings. Furthermore, new methodologies for the detection and analysis of micro- and nano-scaled materials and surface structures were added to the portfolio.

The approach of the Smart Material and Surface Testing division includes the application of common measurement techniques as well as the development of new test set-ups and evaluation methods. The results obtained help to optimize production processes and provide guidelines for advancements in material and component development. One important aspect is the transfer of scientific knowledge to an industrial environment. Another aspect worth mentioning is the definition and implementation of methods ranging from incoming inspection of materials to quality and process control to reliability and aging testing. Here, special attention is paid to non-destructive methods that can be self-intelligent, fully automated and integrated into quality inspection systems. These capabilities allow manufacturers to plan the functionality and control the quality of a new product right from the concept and design phases.

Several filed patents demonstrate the successful exploitation of project results, and several awards and prizes established by industry and governmental bodies have been won over the past years.

Scientific approach

From a scientific point of view, the Aging Behavior of Polymers research group aims at a comprehensive understanding of material performance from the molecular to the macroscopic level. The research approach establishes relationships between chemical structure, morphology, polymer processing and material performance, providing structure-processing-performance correlations and guidelines for assessing polymer performance under different conditions. The group has specific expertise in planning and implementing accelerated aging tests. This includes proper analysis of the external and internal stresses of polymer products in the respective micro-climate, development of appropriate aging test procedures, definition of suitable degradation indicators as well as comprehensive material characterization. To describe degradation effects of polymers, we use mainly spectroscopic, chromatographic, thermal, thermo-mechanical and mechanical characterization techniques.

From a scientific point of view, the Aging Behavior of Polymers research group aims at a comprehensive understanding of material performance from the molecular to the macroscopic level. The research approach establishes relationships between chemical structure, morphology, polymer processing and material performance, providing structure-processing-performance correlations and guidelines for assessing polymer performance under different conditions. The group has specific expertise in planning and implementing accelerated aging tests. This includes proper analysis of the external and internal stresses of polymer products in the respective micro-climate, development of appropriate aging test procedures, definition of suitable degradation indicators as well as comprehensive material characterization. To describe degradation effects of polymers, we use mainly spectroscopic, chromatographic, thermal, thermo-mechanical and mechanical characterization techniques.

The Robot Vision and Artificial Intelligence research group aims to develop and investigate new methods for detecting anomalies in big data clouds. Structures and defects on 3D-shaped surfaces are analyzed and classified using robot vision methods and neural networks. In the process, machine learning comprises algorithms that are able to generate knowledge based on experience which is provided by a rather small training set of component samples. In the training phase, a deep learning algorithm memorizes the samples, recognizes patterns in the data and predicts anomaly properties even for new and unseen samples. Among a variety of different types of machine learning algorithms, some rather new strategies have been developed over the past few years, enabling graphical processing and, consequently, massive parallel computing. This new group of machine learning techniques is known as “deep learning”. Deep learning is based on neural networks and uses a cascade of a high number of layers of nonlinear processing units, which enables a high data abstraction level. Compelling proof of their outstanding performance in comparison to other methods has been established in many vision applications. The research focus also addresses two major questions: (1) can neural networks be trained by a number of samples that is small enough for practical use in industry applications, and (2) are deep neural networks capable of precisely distinguishing allowed surface structures from anomalies and defects?

The two research groups address a large range of different scientific and technical challenges, from the correlation of surface topography, optical and haptic appearance of polymeric materials and components down to the description of chemical and physical aging processes and their consequences on the polymer property profile and overall material performance. Our approach includes the application of common measurement techniques as well as the development of new test set-ups and evaluation methods.

This highly scientific approach is reflected in numerous publications in high-ranking peer-reviewed journals and conference proceedings in the past 5 years, and in presentations given at leading scientific and technologic conferences worldwide, such as the European PV Solar Energy Conference, the International Photovoltaic Science and Engineering Conference, the European Weathering Symposium, International Conference of Computer Vision, International Conference on Learning Representations, the International Conference of Machine Learning & Applications as well as the ANTEC.

12 patents were granted within the division. The researchers are also highly active in organizing workshops as well as serving as members of conference committees (Austrian PV conference) or review experts (EU-PVSEC, Silicon PV) in the field of photovoltaics. The researchers are also part of international communities that organize conferences in the field of robot vision and artificial intelligence (e.g. International Conference of Computer Vision (ICCV), International Conference on Learning Representations (ICLR) and International Conference of Machine Learning & Applications (ICMLA)).

Moreover, constant exchange and dissemination of research results is ensured through active participation in standardization committees (IEC-TC82) and various national and international networking activities (IEA-PVPS Task 13, Austrian Photovoltaics Technology Platform, Smart Plastics Network).

Both group heads (Dr. Oreski and Dr. Gruber) are well respected within their respective fields of expertise and therefore frequently invited as speakers at scientific events. In addition to their R&D work, both group heads are also teaching in the Polymer Engineering and Science master study program at Montanuniversitaet Leoben.