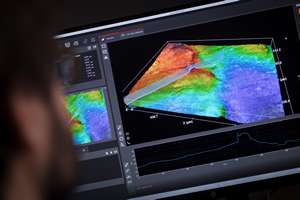

This research group develops industrial-grade surface inspection solutions capable of quantifying the surface quality of 3D-shaped components. The PCCL solutions provide for a complete and reproducible detection and classification of surface anomalies using robot vision and artificial intelligence (AI based on neural networks and deep learning). The results are extremely close to human perception, making these solutions capable of evaluating even 3D-freeform parts. New AI concepts ensure a reliable distinction of surface structures (e.g. decorative patterns) from local surface defects or defective structures. New algorithms also allow for the control of the production processes. Quality drifts are recognized automatically at an early stage, which helps to considerably reduce the number of rejects.

This research group develops industrial-grade surface inspection solutions capable of quantifying the surface quality of 3D-shaped components. The PCCL solutions provide for a complete and reproducible detection and classification of surface anomalies using robot vision and artificial intelligence (AI based on neural networks and deep learning). The results are extremely close to human perception, making these solutions capable of evaluating even 3D-freeform parts. New AI concepts ensure a reliable distinction of surface structures (e.g. decorative patterns) from local surface defects or defective structures. New algorithms also allow for the control of the production processes. Quality drifts are recognized automatically at an early stage, which helps to considerably reduce the number of rejects.

A further research focus aims at the complete identification and quantification of material and surface properties that are responsible for the haptic/touch-feel perception of products. New testing sites for the measurement of surface touch-feel-related parameters such as topography, friction, vibration and material (micro-)ductility were developed at the PCCL. A PCCL USP is the analysis of measurement data using neural networks and deep learning methods to identify specific material and surface parameters that are actually correlated to a surface touch impression. This includes, for instance, determining material properties behind terms such as “froggy”, “leathery”, “silky” and “soft-touch”. Based on such knowledge, polymer materials with tailored surface characteristics are produced to obtain controlled haptic properties.

The PCCL Robot Vision and Artificial Intelligence research focuses on the following activities:

- Surface inspection and characterization of plane and 3D-shaped components of any material

- Surface inspection of large, endless products (extruded products, films, foils, sheets)

- Surface inspection of transparent parts and high gloss surfaces

- Integration of measurement techniques into in-line or ex-situ quality inspection systems

- Artificial intelligence / deep learning aided control both of the quality and the efficiency of production processes

- Methodologies for the detection and characterization of touch-feel properties of material and product surfaces

- Methodologies for the detection of micro- and nano-scaled surfaces structures of any material, including transparent parts or coatings