DELIGHT

DELIGHT - Design and Evaluation of Lightweight Composite PV Modules for Integration in Buildings and Infrastructure

The main objective of DELIGHT is to design, manufacture, and evaluate sustainable lightweight composite PV modules for easier integration into existing infrastructure (buildings, transport infrastructure) with a special focus on increased safety and optimized aesthetic and constructive integration.

Achieving the ambitious targets of decarbonizing the European economy requires huge effort.

Integration of PV into existing infrastructure is one of the main pillars for achieving renewable electricity targets, especially for countries with limited free land to build large-scale PV plants, that are either densely populated (Netherlands, Belgium) or mountainous (Austria, Switzerland).This requires simultaneous optimization of energy yield and cost, module reliability and safety, weight, aesthetics and circularity.

DELIGHT brings together expertise in all these areas and will develop unique solutions for the integration of PV to enable energy neutral and positive buildings.

DELIGHT will focus on increased reliability, safety, optimized aesthetics and constructive integration of PV modules.

The main goals are:

- Reducing the weight of the PV-modules and construction system by achieving targets of ≤ 6 kg/m² (glass free design) and ≤ 7 kg/m² (front glass design)

- Fulfilling aesthetic integration requirements by use of novel, coloured components and coatings

- Optimizing the electrical module design with respect to shadow-tolerant module topologies, improving performance, safety, and reliability under partial shading conditions (module shut-down; disconnection of damaged substrings; hot-spots reduction or elimination)

A cross-sectional goal is to increase the overall lightweight modules’ sustainability by replacing standard fluoropolymer front sheets (expensive and difficult to recycle), with solutions based on coated polyester films, using recycled PET for honeycomb backsheet structures.

DELIGHT will bring the above-mentioned new concepts and solutions to a sufficiently high TRL (6-7), improving eco-design while maintaining performance, quality and reliability.

DELIGHT PV products will be fully designed, manufactured and optimized in EU, to contribute to the European market with high quality and trust.

Partner:

- OFI Österr. Forschungsinstitut für Chemie und Technik

- Rembrandtin Coatings GmbH

- Delft University of Technology

- École polytechnique fédérale de Lausanne – PV Lab

- Kalyon Güneş Teknolojileri Üretim A.Ş.

- EconCore NV

- Solarge International B.V.

- Imec - Interuniversity Microelectronics Centre

- Solaxess

- 3S Swiss Solar Solutions

In order to understand component behavior under application conditions, we use different bulk and surface characterization techniques, such as classical material testing (e.g., tensile, DMA, tear resistance), characterization of long-term performance (e.g., creep, relaxation) as well as cyclic loading and dynamic tests up to 20m/s at temperatures from -40°C up to +250°C.

In order to understand component behavior under application conditions, we use different bulk and surface characterization techniques, such as classical material testing (e.g., tensile, DMA, tear resistance), characterization of long-term performance (e.g., creep, relaxation) as well as cyclic loading and dynamic tests up to 20m/s at temperatures from -40°C up to +250°C.

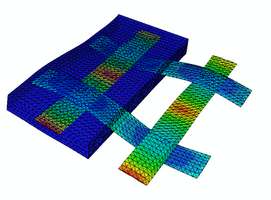

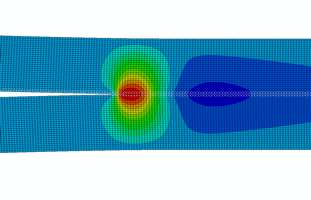

In the field of material modeling for polymer and polymer composite materials the major challenge is the development of new physical models or the adaptation of already existing models and to transfer them into mathematical expressions which are able to describe the particular material behavior at its best. The material behavior of the specific polymer or polymer composite material is investigated in experiments. To ensure an accurate characterization of the material, existing test methods are adapted or new test methods are developed, in some extent. The experimental results provide a basis for the calibration and verification of the material models. The aim is the development of material models which are applicable on real component parts to optimize the process of development. The research field deals for example with

In the field of material modeling for polymer and polymer composite materials the major challenge is the development of new physical models or the adaptation of already existing models and to transfer them into mathematical expressions which are able to describe the particular material behavior at its best. The material behavior of the specific polymer or polymer composite material is investigated in experiments. To ensure an accurate characterization of the material, existing test methods are adapted or new test methods are developed, in some extent. The experimental results provide a basis for the calibration and verification of the material models. The aim is the development of material models which are applicable on real component parts to optimize the process of development. The research field deals for example with In the virtual design development and performance assessment of polymer and polymer composite components the materials complexity necessitate sophisticated approaches and methods. Besides some general methods some solutions need to be specifically developed for defined applications. In most cases the resulting methods are routines based on algorithms developed within the group used in interaction with a finite element solver. Challenges which are worked on are for example

In the virtual design development and performance assessment of polymer and polymer composite components the materials complexity necessitate sophisticated approaches and methods. Besides some general methods some solutions need to be specifically developed for defined applications. In most cases the resulting methods are routines based on algorithms developed within the group used in interaction with a finite element solver. Challenges which are worked on are for example The field of elastomer chemistry strongly focus on the development of new crosslinking strategies (e.g., thermal versus photochemical routes, permanent versus reversible crosslinks) and the curing of rubber and latex materials with low migrating and biocompatible components. In addition, new strategies towards in-situ reinforced elastomer materials are pursued which allow a controlled change of the mechanical performance without significantly affecting processing conditions. Highlights of the research on chemistry of elastomers include:

The field of elastomer chemistry strongly focus on the development of new crosslinking strategies (e.g., thermal versus photochemical routes, permanent versus reversible crosslinks) and the curing of rubber and latex materials with low migrating and biocompatible components. In addition, new strategies towards in-situ reinforced elastomer materials are pursued which allow a controlled change of the mechanical performance without significantly affecting processing conditions. Highlights of the research on chemistry of elastomers include: In this basics-oriented research field, stimuli-responsive polymers are synthetized by introducing photocleavable chromophores (e.g., o-nitrobenzyl ester) and photoreversible binding motifs (e.g., anthracene) into the polymer structure. The smart polymers change their material characteristics in response to an external stimulus such as light or temperature, a fact which is exploited for advanced applications such as:

In this basics-oriented research field, stimuli-responsive polymers are synthetized by introducing photocleavable chromophores (e.g., o-nitrobenzyl ester) and photoreversible binding motifs (e.g., anthracene) into the polymer structure. The smart polymers change their material characteristics in response to an external stimulus such as light or temperature, a fact which is exploited for advanced applications such as: