As part of the strategic research in the PolyComp network and in collaboration with the Vienna University of Technology, the frontal polymerization has been validated as a new process technology for the curing of resins and composites. This method provides the key advantage that the cross-linking of resins is initiated by the irradiation with light, and concomitantly can only be activated by an external stimulus such as irradiation. If the curing of resins is a time-consuming process due to the geometry or the large surface to be bonded for instance, the frontal polymerization and its inherent switchability pave the way for the elimination of inhomogeneities in the cured resin.

The competence network PolyComp (Functional Polymer Composites) investigates innovative material concepts and process technologies with a high potential of industrial marketability in order to develop new materials for electrical engineering and electronics. This network is unique in Austria; aiming at the implementation of these ambitious targets, an international research team collaborates in this interdisciplinary research network.

The bonding of components in transformers and generators is commonly based on the cross-linking of the reactants in the resin mixture: Thereby, bonding is achieved. In case of "classical" cross-linking, the corresponding chemical reactions take place immediately after the mixing of the resin and allow only certain time-windows for bonding. Hence, in case of more complex and therefore time-consuming bonding applications, inhomogeneities in the cured resin occur, with a particularly disadvantageous effect on the mechanical and dielectric properties of the bonded component.

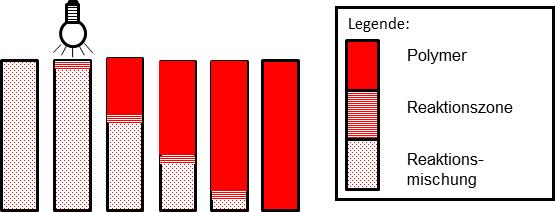

When the frontal polymerization is performed, cross-linking of the resin is started only by a switchable stimulus such as irradiation with UV light. During the crosslinking of the resin, heat is released, which in turn acts as a switch for the cross-linking of the reactants in adjacent areas. Thus, a polymerization front that travels through the resin can be started at a chosen point of time, resulting in a uniform bonding.

Impact and effects:

In comparison with "classic" polymerizations, the frontal polymerization offers the advantage that it can be started intentionally. Inhomogeneities in the cured resin are avoided with a positive effect on the mechanical and dielectric properties of the bonded component, enabling for a more compact design of transformers and generators (higher energy density).

Contact:

PolyComp – Functional Polymer Composites

Univ.-Doz. Dr. Frank Wiesbrock, Key Researcher

Polymer Competence Center Leoben GmbH, Roseggerstrasse 12, 8700 Leoben

Tel. 03842 42962 42; Email: This email address is being protected from spambots. You need JavaScript enabled to view it.; web: http://pccl.at/en/e-polycomp