All polymers and plastics share one common characteristic: They are thermal insulators. The plastics’ inability to transport heat is likely to cause severe trouble in modern electronic devices that are built with continuously higher power density. In order to enhance the thermal conductivity of plastics, they can be filled with particles that inherently provide high thermal conductivity. In the K-Project PolyTherm, such composites were prepared using micro- and nano-scaled fillershe content of fillers varies along one dimension, e.g. the height. In such gradient composites, the heat can be transferred away from the heat source with high efficiency.

Polymers and Plastics: Thermal Insulators

All polymers and plastics share one common characteristic, despite their diversity in function, origin, structure, etc.: They are thermal insulators.

Any material that cannot transport heat may be considered as thermal insulator. In the case of plastics, for example, the inability to transport heat is a well-known characteristic of this material class: Any plastic kitchen material such as food storage boxes will remain wet after the completion of the dishwasher programme, as the heat generated during the drying cycle cannot be stored and transferred/transported within the plastic material.

The plastics’ inability to transport heat is likely to cause severe trouble in modern electronic devices such as smartphones and computers: Every new generation of such devices is built with more functionality, which requires higher power density. If possible, the design of such devices is more compact, which analogously results in higher power density due to the decreased volume of the device. Hence, more heat is developed in such devices, and the temperatures increase during operation.

Plastics are abundantly used in devices such as smartphones and computers, for example as shielding and/or protective materials. If the heat generated during the operation of such a device cannot dissipate through the plastic material (which acts, as said, as a thermal insulator), the temperature is continuously increasing. In the worst case it exceeds a critical threshold, which may result in overall device failure.

Nano- and Microcomposites combined in one: Gradient Composites

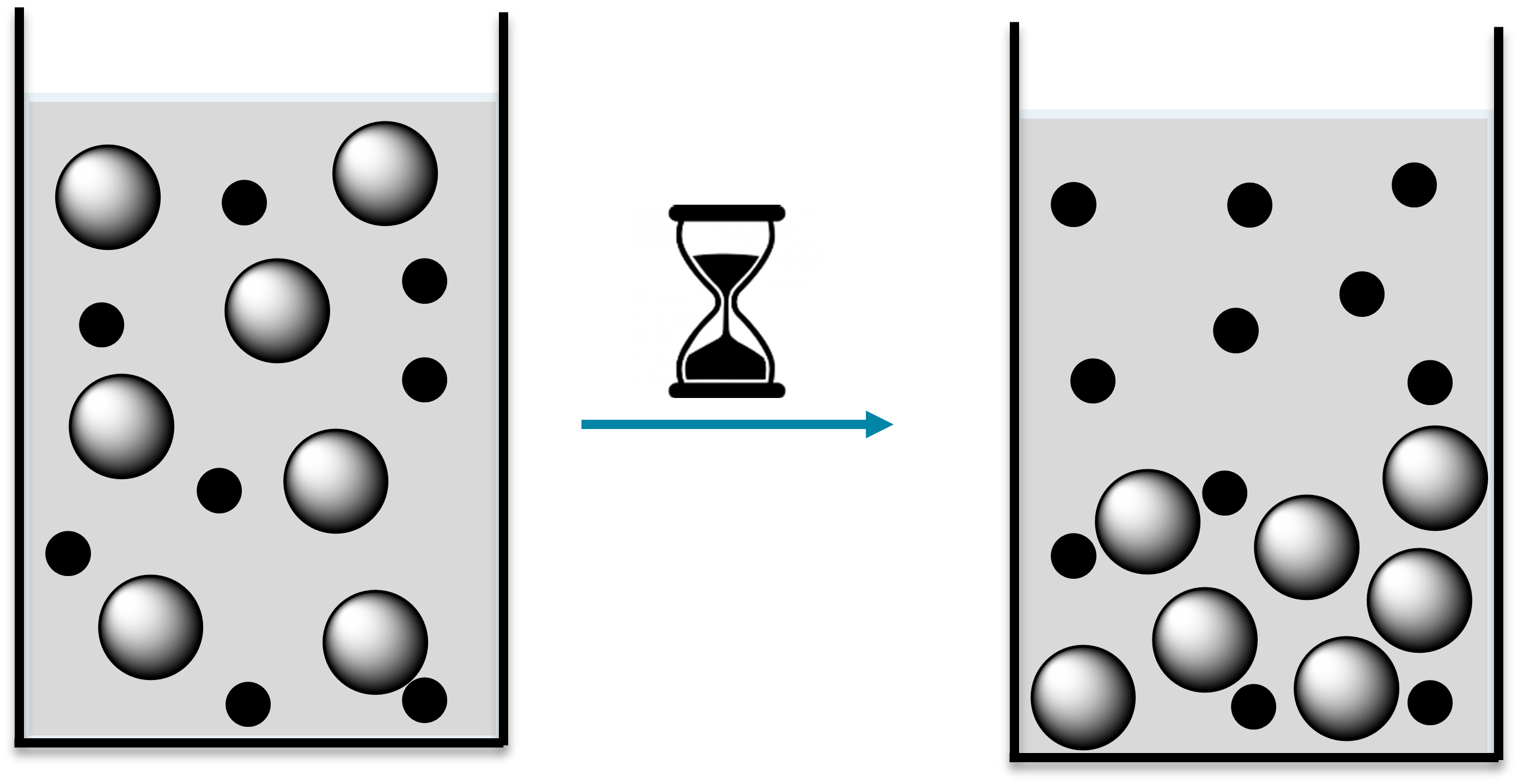

In order to enhance the thermal conductivity of plastics, they can be filled with particles that inherently exhibit high thermal conductivity, such as silica, alumina, boron nitride, aluminium nitride, etc. The size/diameter of such particles varies around several orders of magnitude – starting from nano-scaled diameters (so-called nanoparticles). Compared to microparticles, such nanoparticles are expensive, which renders them less attractive as filler material. Microparticles, on the other hand, are less expensive, but may sink down in a plastic material in its liquid or molten state (resins before curing, and thermoplastics during processing, respectively).

As a rule-of-thumb, it may be argued that the thermal conductivity of a composite material (composed of a polymer matrix and fillers) increases with increased amount of fillers. In the K-Project PolyTherm, such composites were prepared using micro- and nano-scaled fillers, aiming at the fabrication of gradient composites, in which the content of fillers varies along one dimension, e.g. the height.

Impact and effects:

Due to the fast sedimentation of the microparticles (in contrast to the nanoparticles that stay homogeneously dispersed), the material properties of gradient composites such as the thermal conductivity vary along the thickness of the composite. An epoxy-based gradient composite containing micro- and nano-scaled alumina was prepared and cut into thin layers, which were measured by the Light-Flash Apparatus (LFA) that was purchased within the PolyTherm project. It was shown by the experimental data that (at room temperature) the thermal conductivity varied by almost 100% within the composite.

If such gradient composites are built up such that the ‘bottom layers’ (the layers with the high thermal conductivity) are placed on the heat sources of an electronic device, the heat can be transferred away from the heat source with high efficiency. Using this strategy of gradient composites, comparably cheap (cost-efficient) plastic-based materials for modern electronic devices can be obtained. Current modelling & simulation activities within the K-Project PolyTherm dedicatedly address the scientific aspects of heat dissipation through such composites.

Contact:

PolyTherm – Polymers for Thermally Demanding Applications

Univ.-Doz. Dr. Frank Wiesbrock, Key Researcher

Polymer Competence Center Leoben GmbH, Roseggerstrasse 12, 8700 Leoben

Tel. 03842 42962 42; Email: This email address is being protected from spambots. You need JavaScript enabled to view it.;